| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/3. Hệ thống, công cụ và thiết bị phát triển sản xuất điện tử/3.4. Hệ thống dây chuyền sản xuất SMT (SMT Line system)

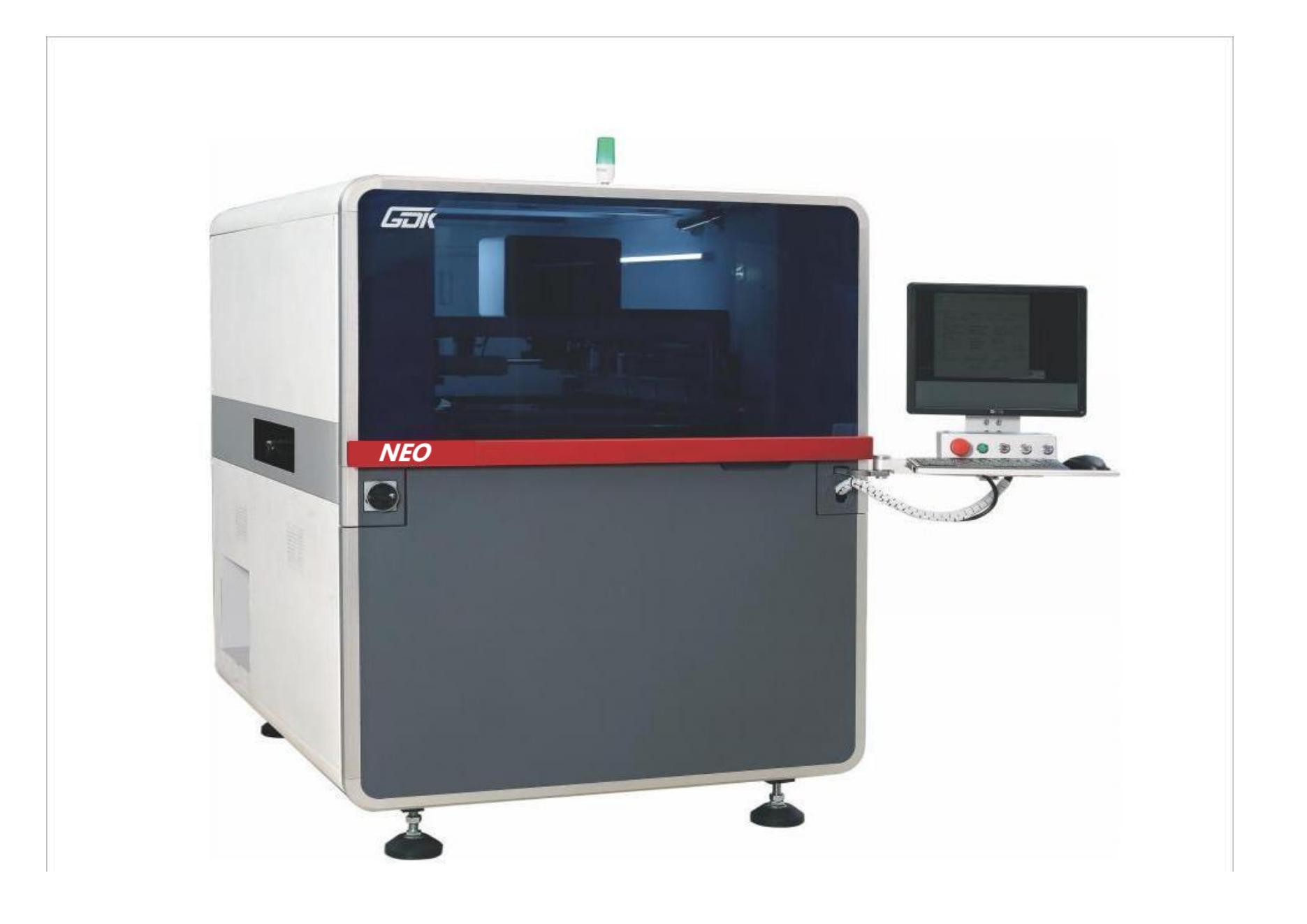

| | | | | ◊ Đặc điểm chính: | | SMT New Automatic Solder Paste Stencil Printer NEO for mini-led

The structure of NEO is simple and reliable,accurate positioning and easy to adjust, aimed at high end application of SMT, especially for LED mini. It can quickly achieve different thickness of the PCB board PIN pin height adjustment of the automatic adjustment. The spray nozzle makes the cleaning liquid evenly sprinkled on the wiping paper, and the arc-shaped rubber wipe board is soft, antiwear and antirust, clean thoroughly bidirectionally, and can be used for dry cleaning, wet wiping, wet cleaning, reciprocating cleaning and other functions..

Alignment precision∶±10.0micron/μm@6σ,Cp≥2.0

Printing precision∶ ±15.0micron/μm@6σ,Cp≥2.0

|

|

|

Technical Parameters:

| PCB Parameter |

| Max. board size(X x Y) |

650mm x 610mm |

| Min. board size(X x Y) |

50mm x 50mm |

| PCB thickness Range |

0.4mm~6mm |

| PCB Warpage |

≤1%Diagonal |

| Max. board weight |

5Kg |

| PCB edge clearance |

Configuration to 3mm |

| PCB bottom clearance |

20mm |

| Conveyor speed ( Max.) |

1500mm/s(Max) |

| Conveyor height |

900±40mm |

| Conveyor direction |

L-R,R-L,L-L,R-R |

| Transfer mode |

One stage orbit |

| PCB damping method |

Proarammable flexible side pressure+ Adaptive PCB board thickness+

Edge lock base clamp. (optional: 1,Multipoint partial vacuum at the bottom;

2,Edge locking and substrate clamping)

|

| Support method |

Magnetic thimble + Equal high block.(Optional:1.vacuum suction cavity;

2.special workpiece fixture)

|

| Printing parameters |

| Print head |

Servo motrdrives prerisionscrew diven suspendedinteliet printing head

two independent diret motos

|

| Stencil frame size |

470mm x 200mm~800 mm x800 mm |

| Max. printing area(X x Y) |

650mm x 610mm |

| Squeegee Material / Angle |

Steel squeegee/ Rubber squeegee(Angle 45°/50°/60° matching the

printing process)

|

| Squeegee length |

650mm (optional with length of 200mm-650mm) |

| Squeegee height |

65±1mm |

| Squeegee thickness |

0.25mm Diamond-like carbon coating |

| Print mode |

Single or double squeegee printing |

| Demoulding length |

0.02 mm - 12 mm |

| Print speed |

0 ~ 200 mm/s |

| Print pressure |

0.5kg - 10Kg |

| Print stroke |

±275 mm(From the center) |

| Cleaning parameters |

| Cleaning system |

1,front-mounted programmable cleaning liquid injection system;2,dry,

wet,vacuum three modes

|

| Length of cleaning and wiping plate |

650mm |

| Optical System |

| Field of view |

8mm x 6mm |

| Printing table adjustment range |

X:±7.0mm,Y:±8.0mm,θ:±2.0° |

| Fiducial Types |

Standard Fiducial type ( Circle, triangle, square, diamond, cross)

(SMEMA standard),solder pad/openings

|

| Vision methodology |

Independent camera,upwards/downwards imaging vision system,

geometric matching location

|

| Performance parameters |

| Machine Alignment repeatability |

±10.0μm @6 σ,Cpk ≥ 2.0 |

| Full process repeatability |

±15.0μm @6 σ,Cpk ≥ 2.0 |

| Core Cycle time |

7.5s(Exclude printing and cleaning) |

| Product changeover time |

<5min |

| Equipment |

| Power supply |

AC220V±10%,50/60HZ,15A |

| Air supply |

4~6Kg/cm² |

| Gas Consumption |

About 5L/min |

| Operating system (OS) |

Windows 7(Optional WIN10) |

| External dimension |

1540mm(L) x 1220mm(W) x 1660mm(H)(Without light,monitor and

keyboard)

|

| Machine weight |

Appro.1230Kg |

| User Permission |

Different users have different permissions (fingerprint identification

entering / password input)

|

| Environment temperat |

23±3°C |

| Relative humidity |

45~70%RH4 |

Standard Configuration:

|

|

1. Accurate optical positioning system

Four way light source is adjustable, light intensity is adjustable, light is uniform, and image acquisition is more perfect; Good identification (including uneven mark points), suitable for tinning, copper plating,Gold plating, tin spraying, FPC and other types of PCB with different colors.

2. High efficiency and high adaptability stencil cleaning system

The new wiping system ensures full contact with the stencil ; three cleaning methods of dry, wet and vacuum, and free combination can be selected; soft wear-resistant rubber wiping strip, thorough cleaning, convenient disassembly, and universal length of cleaning paper.

3. Intelligent squeegee system

Intelligent programmable setting, two independent direct motors driven squeegee, built-in precise zero pressure detection system.

4. GDK Special PCB thickness adaptive system

The platform height is automatically calibrated according to PCB thickness setting, which is intelligent, fast, simple and reliable in structure.

5. Printing axis servo drive

The squeegee Y axis adopts servo motor drive through screw drive,to improve accuracy grade,operational stability and extend the service life,to provide a good printing control platform.

6. 2D solder paste printing quality inspection and SPC analysis

2D function for offset, less tin, leakage, tin bridge and other printing problems can be quickly detected, the detection point arbitrary increase; The SPC software can analyze the samples collected by the machine CPK index ensures printing quality.

7. Temperature and humidity monitoring function 7. Temperature and humidity monitoring function

Monitor the temperature and humidity inside the printer to ensure that meet the production requirements.

8. Support MES system

The printer automatically generates and saves LOG files (status, parameters) during the production process, which can be perfectly integrated with the MES system to support Industry 4.0. |

Available Options Configuration:

|

|

1. Automatic solder paste filling function

Regular and fixed point automatic addition of solder paste, to ensure the quality of solder paste and the amount of solder paste in the stencil. In order to ensure that can carry out the quality of stable and continuous printing for a long time, improve productivity.

2. Automatic dispensing function

According to different printing process requirements, the PCB can be carry out accurate dispensing, tin dispensing,ine drawing, filling and other functional operations.

3. Squeegee pressure close-loop feedback control

By compensating the light source above the stencil, CCD is used to check the mesh in real time,so as to quickly detect and judge whether the stencil is blocked after cleaning,and carry out automatic cleaning, which is a supplement to the 2D detection of PCB.

4. Paste height monitor

Real time paste height monitor, and trigger the auto filling. Effectively avoid the problem of insufficient solder paste in printing

5. Stencil Inspection System

By compensating the light source above the stencil, CCD is used to check the stencil in real time, so as to quickly detect and judge whether the stencil is blocked after cleaning, and carry out automatic cleaning, which is a supplement to the 2D detection of PCB.

6. Magnetic squeegee

Magnetic adsorption squeegee blade,instead of screw hole positioning mode, convenient and quick replacement.

7. Vacuum suction plate and upperpress function

It can automatically clamp PCB of various sizes and thicknesses to effectively overcome the deformation of the board,Make sure that the tin is evenly printed.

8. SPI close loop system

With the SPI closed-loop feedback system, the printer will automatically adjust and correct the platform based on feedback for poor print quality. This will help improve print quality |

Other Available options Configuration:

| Item No. |

Function |

| 1 |

Paste Roll Height Monitor (aPRHM) |

| 2 |

Internal temperature and humidity detection on the work area |

| 3 |

Window 10 system |

| 4 |

Upper Press Function |

| 5 |

PCB Size 525 mm * 350 mm |

| 6 |

PCB board support method Grid-Lock |

| 7 |

Support pins or support block detection sensor |

| 8 |

Squeegee holder |

| 9 |

System of adding solder paste from cartridge Semko 6 Oz |

| 10 |

Control - by touch screen monitor |

| 11 |

PC must have (SSD) |

| 12 |

Range of adjustment feets from 45 to 160 mm |

| 13 |

6.1 Software can save log-files

6. 2 Log-files contain data about all possible parameters of the equipment

6.3 Discreetness of data saving may be set up without limits

6.4 Export of log-files to Excel or Access

6.5 Alarm system in case of parameters are not correspond to preset parameters

6.6 Possibility of remote export of log files

6.7 For all parameters of the equipment there will be possibility of setting up of critical value of such parameters and further actions (means stoppage or further work with indication and information in separate log-file) with marks in log-files only in case of preset parameters will go beyond critical value. |

| 14 |

UPS |

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM GDK |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

GDK SMT Automatic Solder Paste Stencil Printer NEO for mini-led: Máy in kem hàn tự động, Model NEO

GDK SMT Automatic Solder Paste Stencil Printer NEO for mini-led: Máy in kem hàn tự động, Model NEO

7. Temperature and humidity monitoring function

7. Temperature and humidity monitoring function