| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/3. Hệ thống, công cụ và thiết bị phát triển sản xuất điện tử/3.4. Hệ thống dây chuyền sản xuất SMT (SMT Line system)

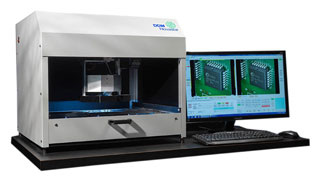

| | | | | ◊ Đặc điểm chính: | | Cost-effective compact batch reflow oven provides forced air convection heating technology with individual time and temperature controls to make profile set up quick and easy. The single zone GF-B-HT comes in a table-top configuration or with an optional stand. It has a high temperature model capable of lead and lead-free soldering and 2 cooling stations making it the best reflow oven for the money.

This unique PCB shuttle system enables a higher throughput than standard batch ovens. Both sides of the oven have a cooling station. While one board is being processed, another board can be cooled and off-loaded, then a third board can be loaded and shuttled into the chamber for reflow.

- Low-cost reflow oven best for small batch runs and prototypes.

- Large window allows the operator to see the board throughout the entire reflow process

- Unique shuttle system enables higher throughput than standard batch ovens

- All stainless steel interior construction provides for years of useful life

- Nitrogen gas inerting option available

- Maximum board size is 12" x 12" (305mm x 305mm)

- Compatible with lead and lead-free soldering applications

|

|

|

Lò hàn tái tạo hàng loạt nhỏ gọn tiết kiệm chi phí cung cấp công nghệ gia nhiệt đối lưu không khí cưỡng bức với các điều khiển thời gian và nhiệt độ riêng để giúp thiết lập hồ sơ nhanh chóng và dễ dàng. Vùng đơn GF-B-HT có cấu hình đặt trên bàn hoặc với giá đỡ tùy chọn. Nó có mô hình nhiệt độ cao có khả năng hàn chì và không chì và 2 trạm làm mát khiến nó trở thành lò nung nóng lại tốt nhất với số tiền bỏ ra.

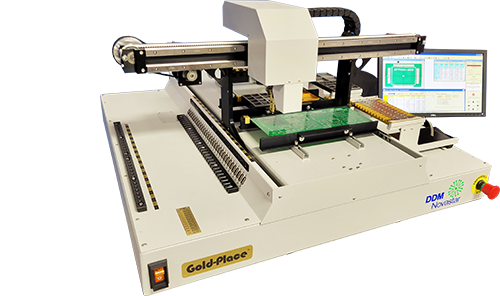

Lò hàn gia công theo lô, DDM Novastar Model GF-B-HT Hệ thống con thoi PCB độc đáo này cho phép thông lượng cao hơn so với lò nướng theo lô tiêu chuẩn. Hai bên lò đều có ga làm mát. Trong khi một bo mạch đang được xử lý, một bo mạch khác có thể được làm mát và tháo tải, sau đó một bo mạch thứ ba có thể được nạp và đưa vào buồng để làm nóng lại

- Lò nấu lại chi phí thấp tốt nhất cho chạy hàng loạt nhỏ và nguyên mẫu.

- Cửa sổ lớn cho phép người vận hành nhìn thấy bảng trong toàn bộ quá trình chỉnh lại

- Hệ thống con thoi độc đáo cho phép thông lượng cao hơn so với các lò sấy tiêu chuẩn

- Tất cả các công trình nội thất bằng thép không gỉ cung cấp cho cuộc sống hữu ích nhiều năm

- Có sẵn tùy chọn làm trơ khí nitơ

- Kích thước bảng tối đa là 12 "x 12" (305mm x 305mm)

- Tương thích với các ứng dụng hàn chì và không chì

| Max board width |

12" x 12" (305mm x305mm) |

| Max board height |

1.250" (32mm) |

| Heating zones |

One (1) |

| Max temperature |

315°C (600°F) |

| Heat tunnel length |

NA |

| CyclonicsTM (forced air) |

One (1) |

| Conveyor extensions |

Dual board shuttle |

| Cooling station(s) |

Two (2) |

| Venting |

4" (102mm) flange with integral fan |

| Cooling Zone Venting |

N/A |

| Nitrogen option |

Yes |

| PC Interface |

No |

| Overall dimensions (L x W x H) |

38.13" x 28.13" x 14.5" (968mm x 715mm x 368mm) |

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM DDM NOVASTAR |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

GF-B-HT: Batch Reflow Oven

GF-B-HT: Batch Reflow Oven

.gif)